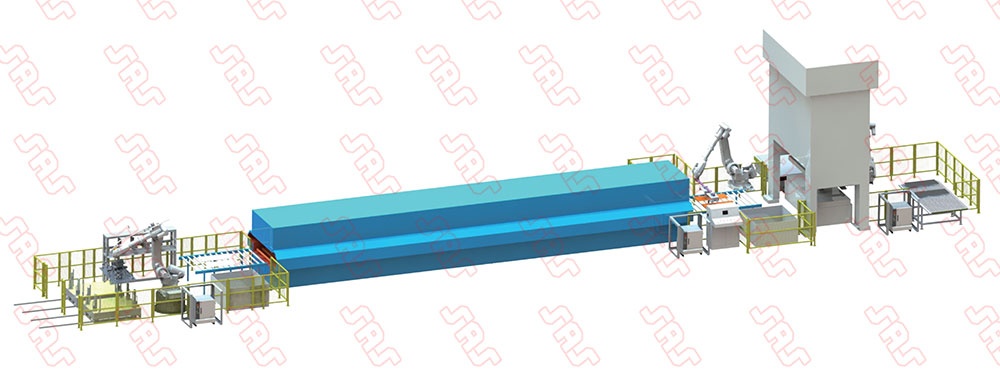

Hot Stamping Line

The high-strength steel hot forming automatic production line is an automatic production line integrating material conveying, coding, heating, anti-oxidation, stamping, quenching, cooling, cutting and shot blasting. The high-strength steel plate is heated to 900-1000℃, stamped and formed and rapidly cooled and quenched to realize the transformation from austenite to martensite, thereby obtaining workpieces with higher strength (1200-1500MPa) and higher hardness, which can be widely used It is used in the forming of automobile body parts to realize the lightweight of automobiles and improve the safety of automobile collisions.

Composition:

Line head depalletizing unit 2x mobile destacking trolleys 2x Manual Magnetic Arm Automatic Spreading System 1x 6-axis robot 1x depalletizing end picker (universal) 1x Double Sheet Detection System 1x coding system Oven and centering unit 1x heating furnace and centering system (customer provided) Feeding unit 1x 6-axis robot 1x feeding robot end picker | End of line receiving unit 1x 6-axis robot 1x unloading robot end picker 1x Receiving belt conveyor Safety protection unit 1x whole line safety fence 1x full line safety lock and control Electrical control unit 1x total control system 3x QuickStamp special software for stamping robot automation |

Main parameters:

The fastest feeding speed 2.5-3.0S

Optional:

Production line MES production management system Production status display system Video Surveillance System | End-of-line automatic packing system High temperature detection system |